Pad Printing Machines

Pad printing machines, also known as tampon printing machines, are equipment used to print images, text, or designs on a variety of three-dimensional surfaces, including plastic, metal, ceramics, and glass. They operate through a process of transferring ink from an engraved metal plate to a silicone pad, which then transfers the ink onto the printing surface.

These machines are highly versatile and can be adapted to print on a wide range of shapes and sizes of objects, making them ideal for product customization and mass production of items such as toys, tools, electronic devices, among others.

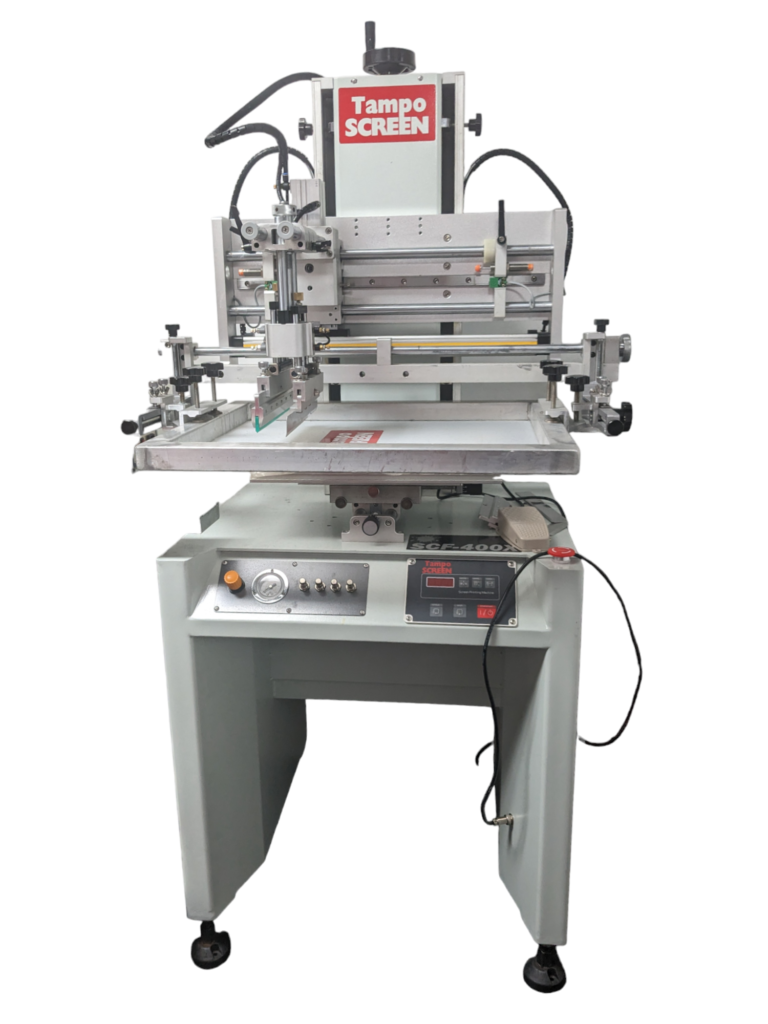

Screen Printing Machines

Screen printing machines, also known as silk screen printing machines, are equipment used for the process of screen printing, a versatile printing technique suitable for various substrates such as fabric, paper, metal, and plastic. These machines typically consist of a frame with a stretched mesh screen, where a stencil is created to allow ink to pass through onto the substrate. The process involves preparing the design, coating the screen with a light-sensitive emulsion, exposing it to light, washing out the unexposed areas to create the stencil, applying ink onto the screen, and using a squeegee to push the ink through the stencil onto the substrate. Screen printing machines come in various sizes and configurations, ranging from manual to automatic, to accommodate different production needs. They are widely used in industries such as textiles, electronics, and signage due to their ability to produce vibrant and durable prints with high detail and versatility across different materials.

Pad Printing Supplies

Pad Printing and Screen Printing Inks

“Our inks serve a multitude of purposes, catering to both pad printing and screen printing applications. We offer a diverse selection of inks tailored for various materials including glass, metal, ceramic, plastic, acrylic, and more. Our commitment to quality ensures that our inks deliver exceptional results, guaranteeing longevity and durability across all substrates.”